The company encountered a recurring challenge in its manufacturing process. Hand tools were utilized during the labor process to shape large batch custom parts. However, this approach posed several issues, including significantly increased time on complex parts, lack of consistency, and long-term fatigue on employees.

MANUFACTURE SOLUTIONS

The Solution

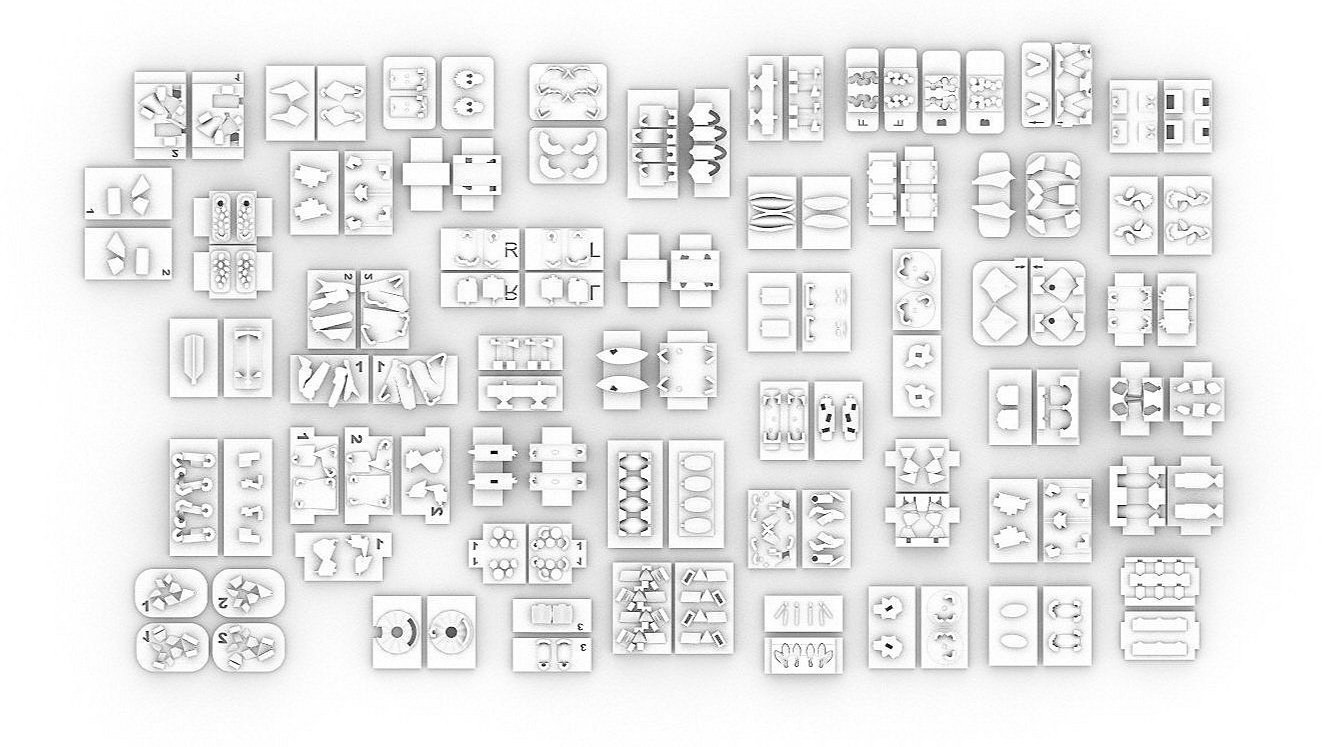

Custom Made Kick Press with Digitally and Hand Crafted 3D Printed, Laser Cut, Steel and Aluminum Components

David Howell

& Company

Specializing in the design and manufacturing of sophisticated, museum quality gifts, including metal bookmarks, jewelry, ornaments, and more. Our innovative gift designs are inspired by museum pieces, adapting original, iconic work to modern, meaningful gifts.

Me Creating Kick Press Modification

Kick Press Modification

To address the challenges faced by the company, I initiated the process by identifying an old kick press. Subsequently, I detached the jaws and proceeded to modify the press. Utilizing recycled machine parts, I engineered a sliding base equipped with a magnetic stopper. This innovative design allowed users to seamlessly slide parts in and out of the jaws with ease and consistency.